FDA regulations are crucial in the medical device industry. The FDA 21 CFR Part 820 which is also known as the Quality System Regulation, sets out the Current Good Manufacturing Practice (CGMP) standards for the development of, production and distribution of medical devices. The FDA 21 CFR Part 820, also known as the Quality System Regulation, provides current good manufacturing practices (CGMP) guidelines to be followed in the design, manufacture and distribution of medical devices.

Understanding FDA 21 CFR Part 820 Compliance

FDA 21 CFR 820 provides an exhaustive list of standards to which medical device makers must conform to ensure the safety and effectiveness of their products. The requirements are based on various aspects of manufacturing, such as design control, document control, preventive and corrective actions (CAPA) manufacturing and process control, and more. By adhering to these rules manufacturers show their commitment to producing top-quality, safe, and efficient medical devices.

Navigating the complexities of FDA 21 CFR 820 compliance may pose substantial challenges for medical device manufacturers. The sheer volume of regulations, coupled with the need to maintain meticulous records and documentation, can be daunting. The dynamic nature of this business also demands the ability be able to quickly adjust to any changes in regulations or updates. Therefore, manufacturers need efficient systems and tools to improve compliance and assure that they are always aligned to FDA regulations.

What are the main functions of QT9 Software?

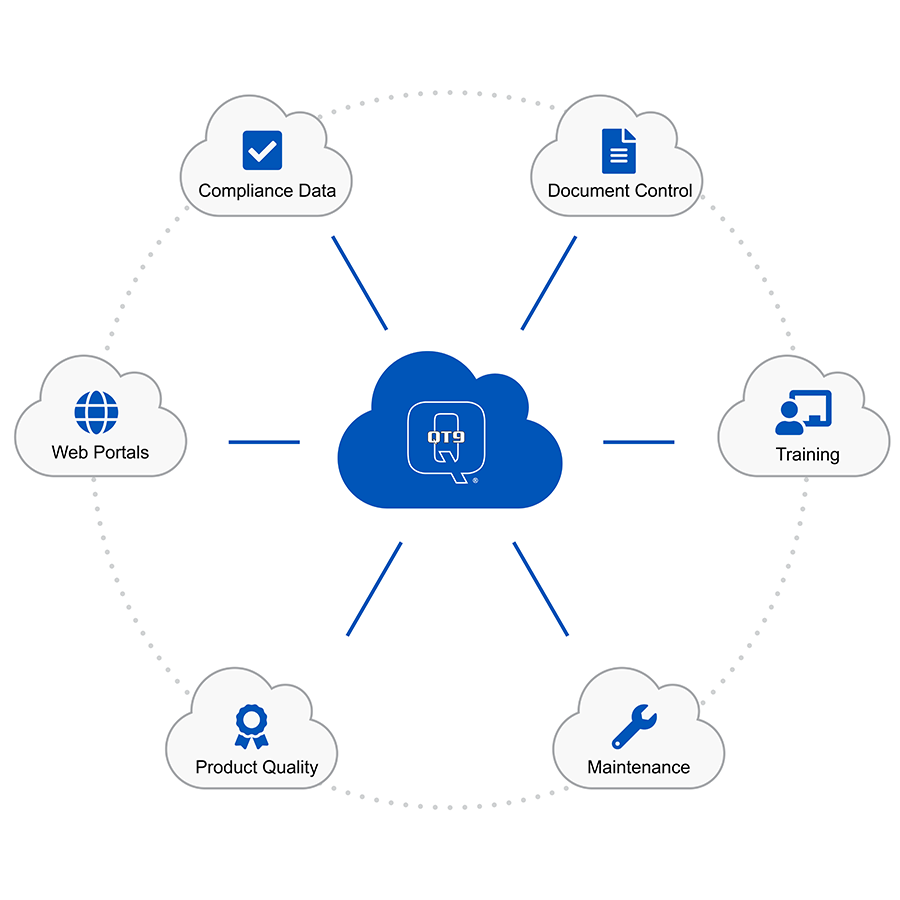

The QT9 QMS offers a comprehensive solution to medical device manufacturers trying to attain and maintain FDA compliance with 21 CFR Part 820. The quality system was developed to meet the needs of the medical device sector. It provides a set of functions and tools which enhances the overall quality management procedures and aids in compliance.

QT9 QMS’s ability for streamlined compliance is among its key benefits. The software integrates the entire documentation and quality process that allow manufacturers to control and monitor compliance actions. QT9 is a single platform to manage all aspects FDA 21 CFR Part 820 compliance, including design control, risk management, supplier management and audit management.

QT9 QMS gives manufacturers real-time reporting options, enabling them to gain valuable insights into their compliance and the quality of their performance. The dashboard of the software provides full overview of compliance metrics, non-conformances and corrective measures, enabling those involved to make informed decisions and take proactive actions to address any compliance concerns that may occur. This information is vital to keeping compliance in place and ensuring continuous improvement.

Customization and adaptability

QT9 QMS allows manufacturers to alter the software to suit their needs for compliance and organizational processes. It can be customized to meet the particular requirements of each manufacturer, be it via modifying workflows or constructing custom forms. It also lets the definition of user roles as well as permissions. This flexibility allows compliance efforts to be in line with organizational specifics which improve efficiency and effectiveness.

Medical device manufacturers can increase their compliance by using QT9 QMS. The software automates various methods of quality management, lessening the workload of manual work and allowing teams to concentrate on more strategic initiatives. QT9 QMS’ centralization encourages collaboration and communication between departments.

Compliance The Future is Here

It is vital to keep up-to-date with the ever-changing regulatory landscape, and adapt to new changes. QT9 QMS offers medical device manufacturers with the tools required to comply in the near future. The software can be adapted to changes in regulatory requirements. Software such as QT9 QMS has options that let manufacturers remain flexible and adaptable when regulatory changes are made.

In conclusion, FDA 21 CFR Part 820 compliance is the cornerstone of the medical device industry, and achieving and maintaining compliance is vital to ensure the safety and efficacy of medical devices. QT9 QMS functions as an instrument to help comply. It is robust and flexible, providing real-time information and increasing the overall efficiency and effectiveness. As the landscape of manufacturing medical devices continues to change QT9 QMS is at the forefront of innovation, allowing manufacturers to manage the challenges of compliance with confidence and agility.