In the ever-changing world of electronics innovation is the key to staying ahead of the curve. Manufacturers are always looking for new ways to revolutionize the assembly of products because demand is growing for smaller, flexure, and high-performance electronics. One revolutionary technology that has gained significant attention is flex circuit manufacturing.

Flexible printed circuit boards, also known as Flexible Circuits (PCBs) offer a variety of advantages over rigid PCBs. These circuits bend, twist, and adapt to different forms. They are perfect for applications that require complex designs, a limited amount of space, or a greater durability.

Flexible circuits enable manufacturers to extend the design limits by providing an elastomeric base that can adjust to the shape and size of the item. This flexibility allows for more creative and compact designs, ultimately which results in lighter and smaller devices. Imagine a smartphone that swivels effortlessly around your hand. or a health monitor that is discreetly tucked into your wrist. Or even a smart device with an ergonomic, seamless design. Flexible circuits enable designers and engineers to turn these concepts into reality, unlocking a new world of possibilities for product development.

The strength and durability of circuits that are flexible is what sets them apart from rigid circuits. PCBs that are made of rigid materials are susceptible to damage due to vibration or shock as well as repeated bends. But flex circuits are made of special materials that are able to withstand these conditions, making them extremely reliable in harsh conditions. This is particularly important in the fields of automotive, aerospace, and medical in which electronic components are exposed to harsh conditions.

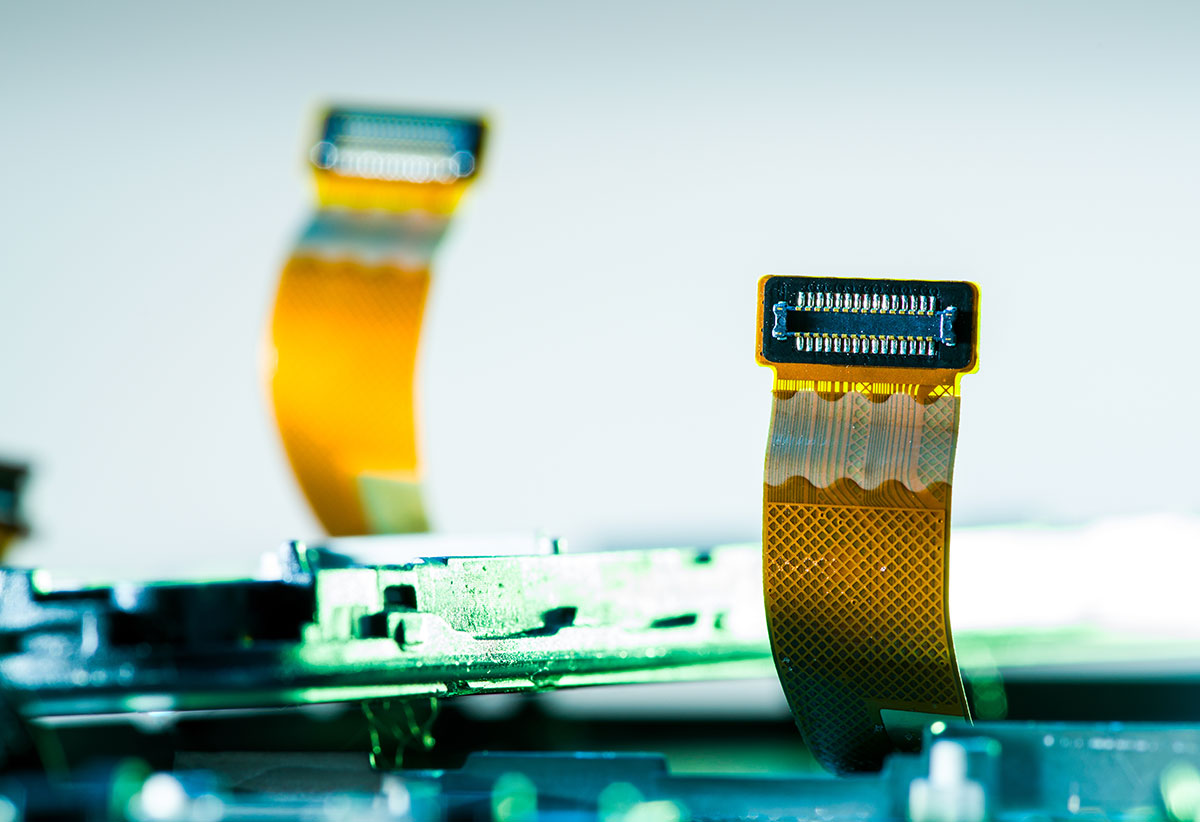

The manufacturing procedures utilized to make flexible circuits are a major factor in their amazing capabilities. In contrast to rigid PCBs made of multiple layers of fiberglass and copper Flex circuits are created by using a flexible, thin substrate material such as polyimide or polyester. The substrate forms the foundation of the circuit and allows it to be bent and bent while keeping electrical connectivity. Flexible circuit makers use sophisticated manufacturing techniques that precisely etch circuit traces, include intricate interconnects or connect components directly on the flexible substrate.

Surface mount technology also referred to as SMT, allows for the integration of devices onto the flex circuit’s surface. This allows for greater versatility and functionality of the circuit. SMT allows manufacturers to mount electronic components directly on circuits that flex. Bulky connectors are eliminated and overall device size can be reduced. This streamlined method not only improves signal integrity, it also reduces weight and enhances thermal control.

Additionally, the manufacturing methods of flex circuits enable efficient prototyping and scalable production. The flexibility of the circuit design enables a rapid prototyping phase, accelerating the development of products. Flex circuits are also economical for manufacturing in large quantities, as they can be produced in large quantities using automated manufacturing techniques. This makes flex circuits the ideal option for companies that want to get their innovative ideas on the market in a short time.

It is vital to be able to rely on a reliable source for flexible circuits because the demand increases. In order to ensure the highest quality, accuracy, and consistent manufacturing of flex circuit it is important to work with reputable and experienced manufacturers. These companies have the knowledge to assist clients throughout the manufacturing and design process as well as provide valuable advice on the selection of materials, and guarantee compliance with industry standards.

Flex circuits are essential components that enable modern electronic assembly systems to reach the most advanced possible degree of complexity. Flex circuits are the heart of a variety of complex systems, from displays used in consumer products to military applications. Because they can move easily across small areas, flexible substrates offer engineers the capability to make their designs feature-rich and still fit into tiny footprints of assembly. While it’s true that a variety of other forms of circuit routing exist, their mechanical and electrical features aren’t nearly as good as those provided by the flex assembly solution when it comes to meeting tough size restrictions. Flex circuits are a suitable option for projects that require intricate interconnections, combining multiple technologies in one well-designed package.